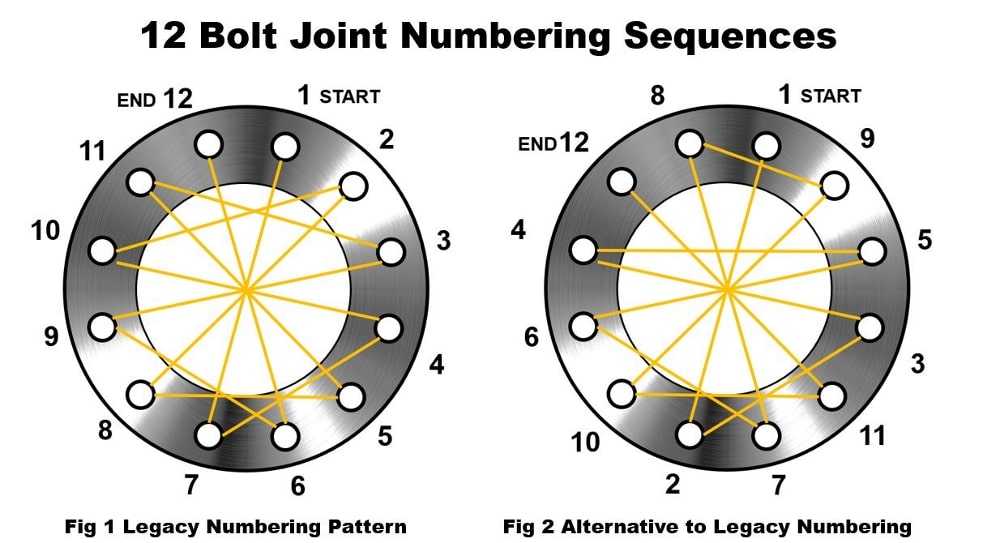

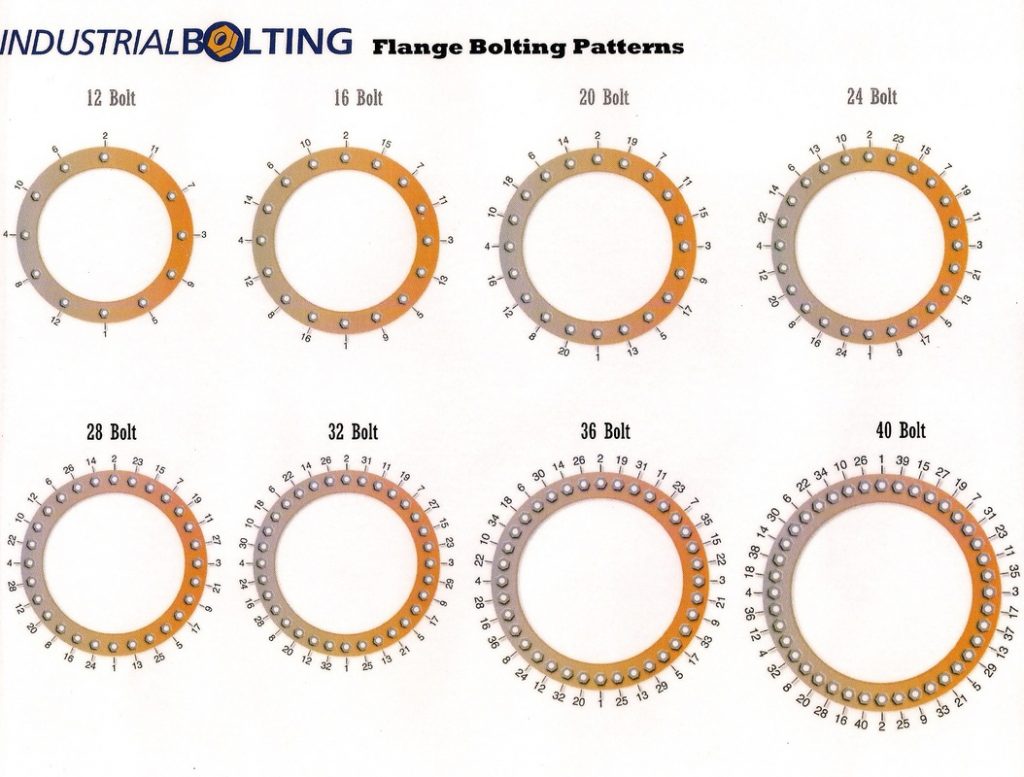

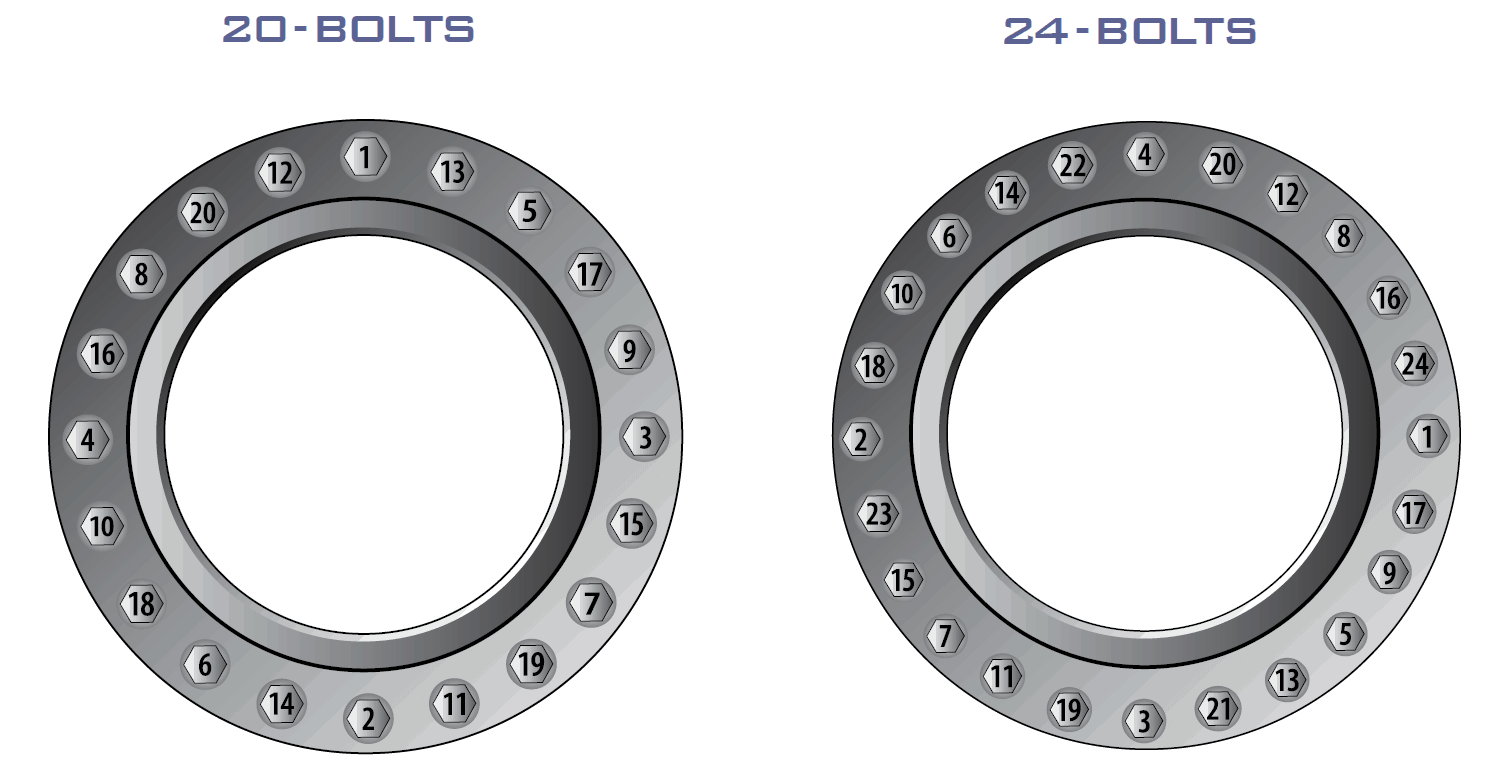

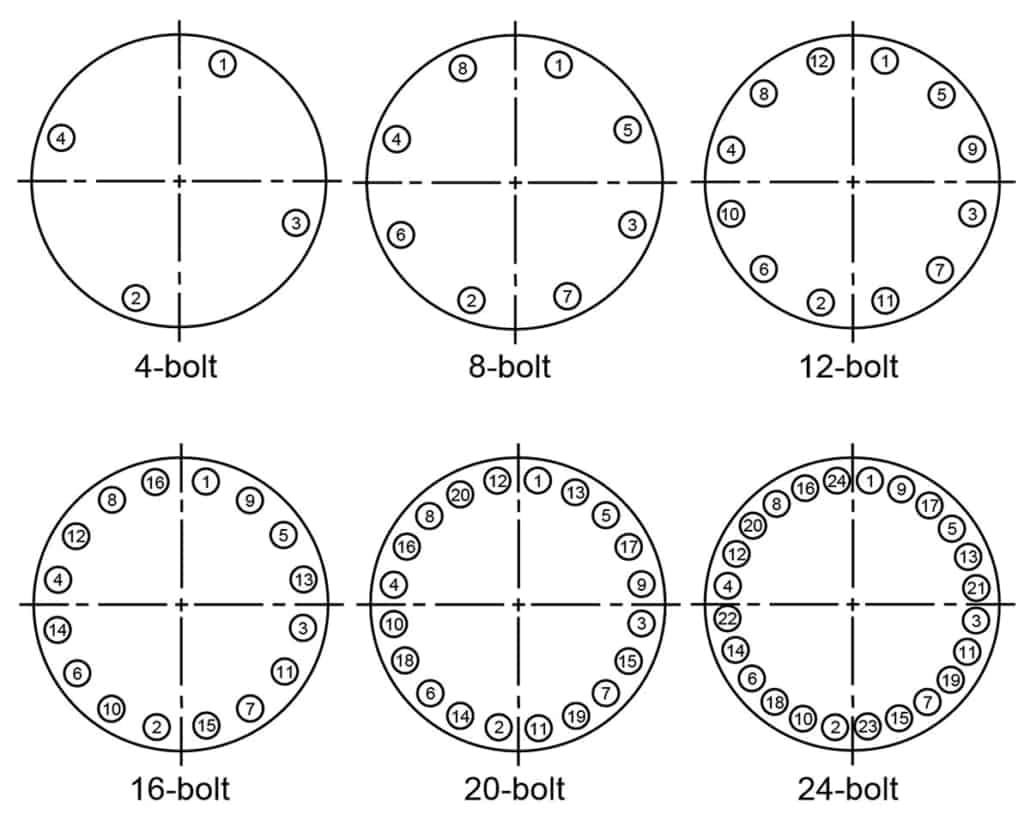

Determining the correct torque can however present problems. Web flange bolt torque patterns. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Look up torque specification — use a. Web flange bolt torque sequence.

Web 4 and 8 bolt flanges: The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Determine bolt size — find the diameter and thread pitch of the bolt. Determining the correct torque can however present problems. Shown is the bolt tightening sequences for typical circular flanges.

Web the importance of correct bolt tightening cannot be over emphasized. 1, 5, 3, 7, 2, 6, 4, 8. East pompano beach, fl 33060. Shown is the bolt tightening sequences for typical circular flanges. Web these general guidelines are to help identify potential pitfalls relating to the tightening of bolted joints.

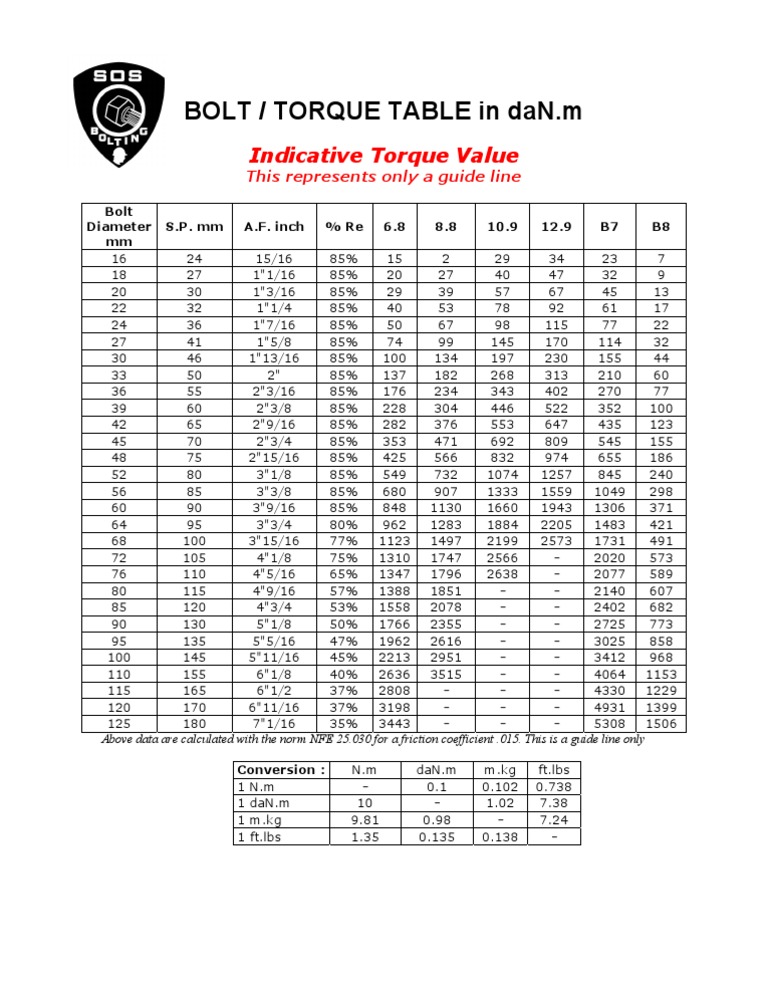

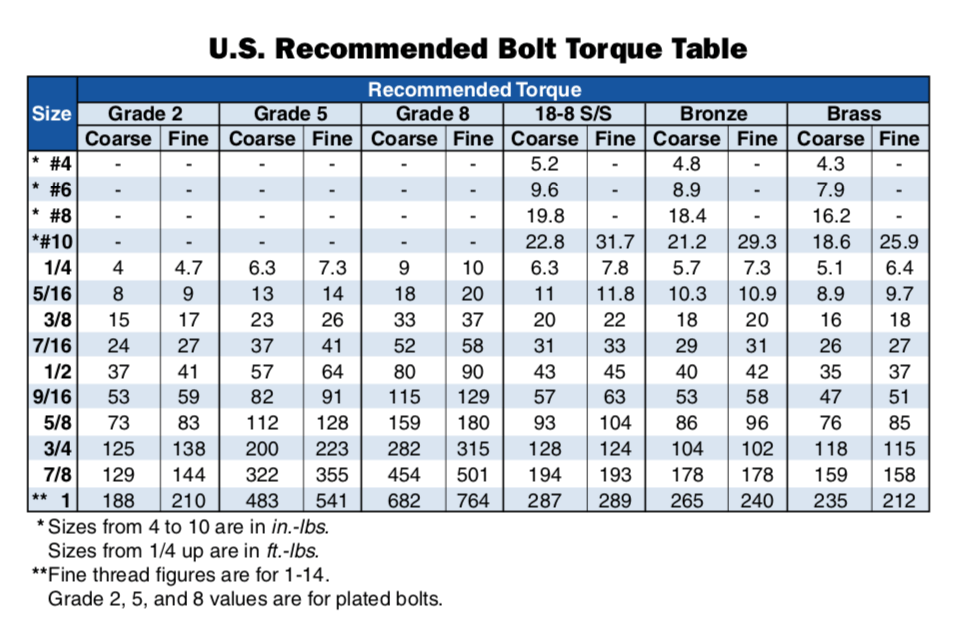

Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. Garlock sealing technologies an enpro industries company. Control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. 1, 5, 3, 7, 2, 6, 4, 8. Web bolt torque chart showing suggested torque values and corresponding bolt clamping forces for various sizes and specifications of fasteners. Web torque pattern for 8 bolt flanges. Web grade 2, 5, and 8 values are for plated bolts. Approximately 90% of the applied. Grade 2, 5 and 8 values are for plated bolts. Web ses 75% of the yield strength. Use a calibrated torque tool: Ensure that a calibrated torque tool is used. Web flange bolt torque patterns. Recommended torque values lubricated stud bolts w/0.15 friction value. Web bolt tightening patterns.

Web These General Guidelines Are To Help Identify Potential Pitfalls Relating To The Tightening Of Bolted Joints.

Web sae bolt grades indicate the strength of the bolt. Web bolt tightening patterns. 1, 5, 3, 7, 2, 6, 4, 8. Recommended torque values lubricated stud bolts w/0.15 friction value.

Web Bolt Torque Chart Showing Suggested Torque Values And Corresponding Bolt Clamping Forces For Various Sizes And Specifications Of Fasteners.

Determining the correct torque can however present problems. Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. Web 4 and 8 bolt flanges: Control the torque applied, the bolting pattern and the tightening sequence to avoid leaks.

Flange Joints Are Torqued Tight With The Help Of A Torque Wrench (Manual Or.

Determine bolt size — find the diameter and thread pitch of the bolt. Web grade 2, 5, and 8 values are for plated bolts. East pompano beach, fl 33060. Approximately 90% of the applied.

The Prevailing Torque Lock Nut Clamp Loads Are Listed At 75% Of The Proof Loads Specified For The Appropriate Grade Bolt:

Web flange bolt torque sequence. Shown is the bolt tightening sequences for typical circular flanges. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | [email protected] 1350 south dixie hwy. Web to calculate the torque required to tighten a bolt: